K9DP 100w BCI Filter Kit Instructions

Please contact me if you have any questions.

Note: These filters have a 50 Ohm impedance and are symmetrical, so it’s not important which end is the input or output.

Caution: To ensure optimal performance and avoid damaging your filter, it’s important to use it correctly while using a tuner. The filter should be inserted inline between the transceiver and tuner, rather than between the tuner and antenna. If your radio has an internal tuner, be sure to use a resonant antenna or an antenna with a matching circuit, such as an EFHW (end fed half wave), in combination with the filter. High SWR (standing wave ratio) with high power can potentially damage the filter.

What you will need

- Phillips #1 screwdriver

- Needle nose pliers

- Soldering iron with a fine tip

- Solder (Such as Kester 63/37 with rosin core)

- Side cutter

- Razor blade

- Helping Hands tool

- Glue (epoxy, super glue, or anything you prefer for gluing toroids)

- Ruler or tape measure

Parts List (If anything is missing contact me)

- (1) 471 Capacitor

- (2) 821 Capacitor

- (4) Toroids

- (2) 18” length of wire

- (4) Pan head screws

- (4) Lock washers

- (4) Hex nuts

- (2) Ring terminals

- (2) Case screws (One screw is already in the case when you receive the kit)

- (1) Printed circuit board

- (2) SO-239 connectors

- (1) Case and case cover

Build Instructions

1. To begin, use a Phillips #1 screwdriver to remove the SO-239 connectors from the case. Then check that all the parts are in the kit using the parts list above. If anything missing, please contact me here.

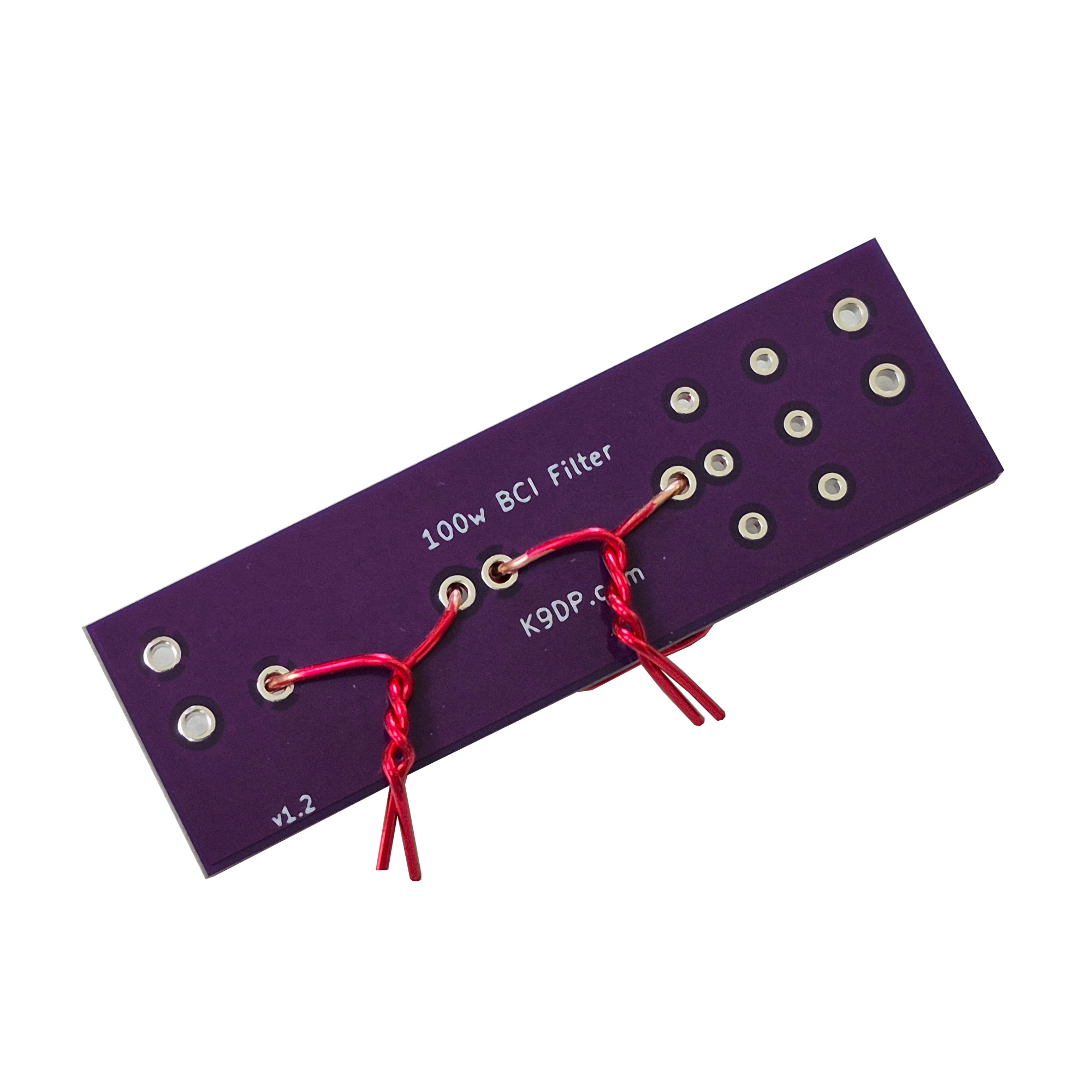

2. Locate the four toroids in the kit. Two toroids need to be stacked and glued together so that you have a pair of double-stacked toroids. Refer to the image below. I personally use a two-part epoxy, but there are many other options such as super glue. Stacking the toroids like this allows for higher power with less heat while keeping the filter small and lightweight.

3. While you’re waiting for the glue to dry locate the three capacitors in the kit. You may need a magnifying glass to read the numbers printed on the capacitors. C1 and C3 on the circuit board are the capacitors labeled “821”, while C2 is the capacitor labeled “471”. To make it easier to solder the capacitors you can slightly bend their leads to hold them in place on the circuit board. Begin by soldering the center “471” capacitor onto C2 and then trim the leads with side cutters. Then solder the “821” capacitors onto C1 and C3 and trim their leads as well.

4. Uncoil the enameled wire and separate it into two lengths. Using a ruler or tape measure, cut 1 inch (25mm) of wire twice from each length of wire. You will end up with four 1 inch (25mm) lengths of wire and two 16 inch (41cm) lengths of wire. If you make a mistake, there is some extra wire after winding the toroids in the next step.

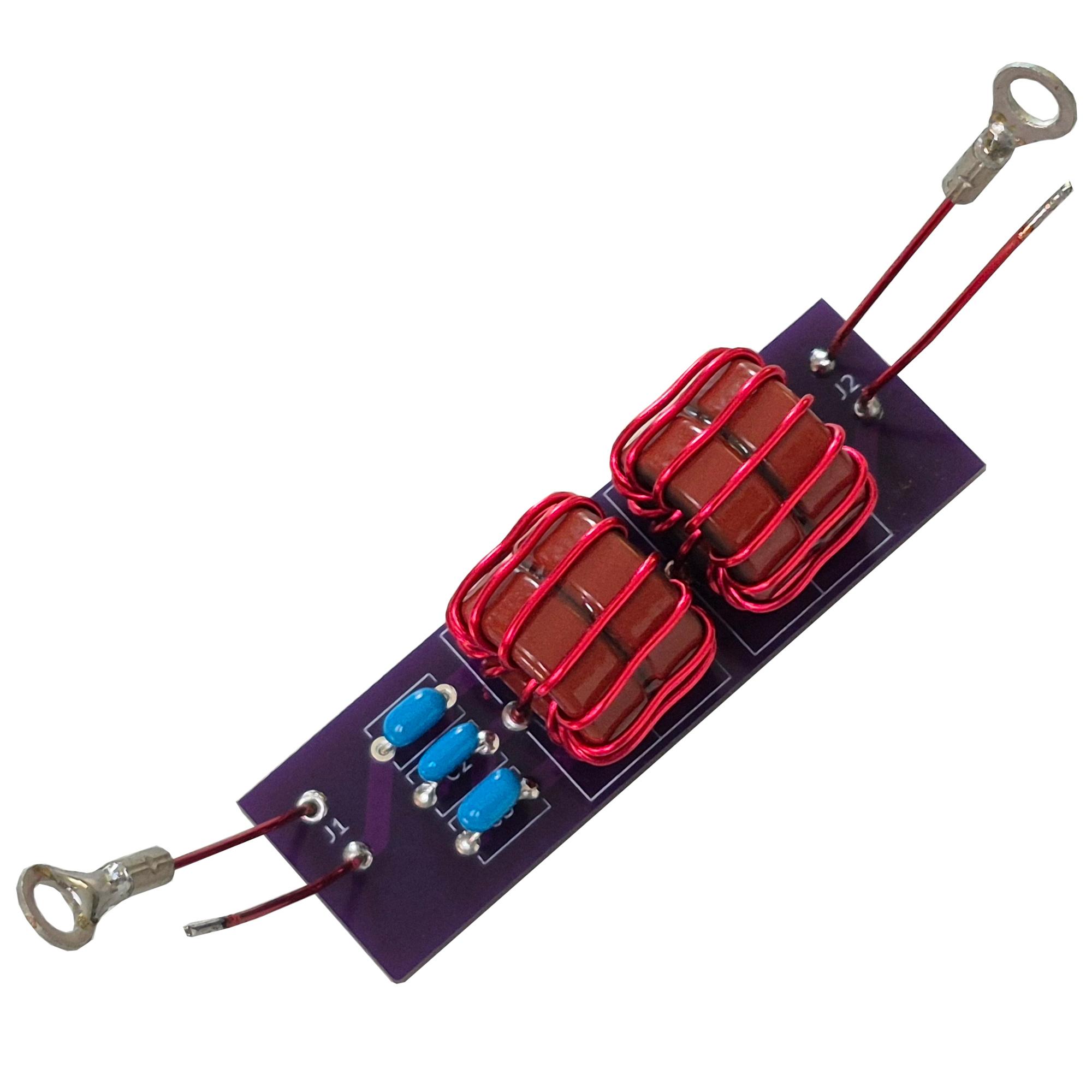

5. Start winding the first toroid, being sure to leave about 1 inch (25mm) of extra wire at the start. Make sure to space the wire windings evenly along the entire toroid as you wind it 13 times around. Once you reach the starting point double-check you have 13 turns. Refer to the picture below for wire spacing and number of turns if you’re unsure. Then cut off the excess wire, leaving about 1 inch (25mm). Repeat this process with the second toroid, winding it the same number of times and spacing the windings evenly. Both toroids should have a total of 13 turns when you are finished.

6. To ensure a solid connection with the printed circuit board (PCB), you’ll need to remove the enamel coating on the wires where they will contact the PCB. Refer to the image below. Use the edge of a razor blade to carefully scrape off the enamel, taking care not to apply too much force and damage the wire. This process may take some time, but it will be worth it to ensure a good connection. If you have soldering experience, you can also melt the enamel while soldering the toroids to the PCB without scraping it off. If you’re unsure, please scrape off the enamel before soldering as a bad connection causes most of the issues I see with building the kit.

7. Feed the wires from one of the toroids into L1 on the PCB. After passing the wires through, flip the board over and twist the wires together tightly to hold the toroid firmly in place. This will make it easier to solder. Follow the same process to attach the second toroid to L2 on the PCB. Refer to the image below.

8. Once you have secured the toroids to the board, proceed with soldering the wires in place. After soldering use your side cutters to trim off the excess wire.

9. Locate the four 1 inch (25mm) lengths of wire from step 4. Place the wire in a Helping Hands tool. Pre-tin each end of the wires. I personally set my soldering iron to 420°C to melt the enamel quickly. Refer to the image below.

10. Locate the two ring terminals in the kit. Place them in a Helping Hands tool and pre-tin the connection with solder for the wires. Then heat the ring terminal with the soldering iron and solder the wire to the ring terminal. The easiest way to do this is to hold the ring terminal with the Helping Hands tool and hold the wire with needle-nose pliers. When finished you should have two ring terminals with wires and two pre-tinned wires. Refer to the image below.

11. Place the PCB into the Helping Hands tool. Place the ring terminal in the Helping Hands tool. Position both so that they are in the outermost hole of the PCB with just a slight amount (~1mm) of wire protruding from the bottom of the PCB. Refer to the image below for wire placement. Solder the wire to the board. Solder the remaining wires to the board, referring to the image below for placement. Trim any excess from the bottom of the board.

12. Place the SO-239 connectors into the Helping Hands tool and pre-tin the center insulator. Be sure to fill the “cup” with solder. Refer to the image below.

13. Locate two pan head screws, two lock washers, and two hex nuts. Using one of the pan head screws, attach the SO-239 connector. Use the bottom screw hole. It is important that the SO-239 pre-tinned center conductor is facing up. Ensure that the lock washer is placed inside the case against the hex nut. Refer to the image below.

14. Using a tip of a razor blade and needle-nose pliers, remove the protective red covering from the doubled-sided tape in the case. Then place the filter into the case, make sure that it is centered.

15. Bend the ring terminals into place at the top screw holes. Locate two pan head screws, two lock washers, and two hex nuts. Secure the ring terminals, ensuring that the lock washer is placed between the ring terminal and hex nut. Refer to the image below

16. Bend the center conductor wire so that it meets the SO-239 center conductor. Heat your soldering iron to high heat; I personally use 420°C. Heat the center conductor of the SO-239 until the solder liquefies. Use a needle-nose pliers to solder the wire into the SO-239. Bend the wires out of the way so there is no risk of them touching, refer to the image below.

17. Tighten the SO-239 screws. Using the two case screws, attach the case cover; do not overtighten.

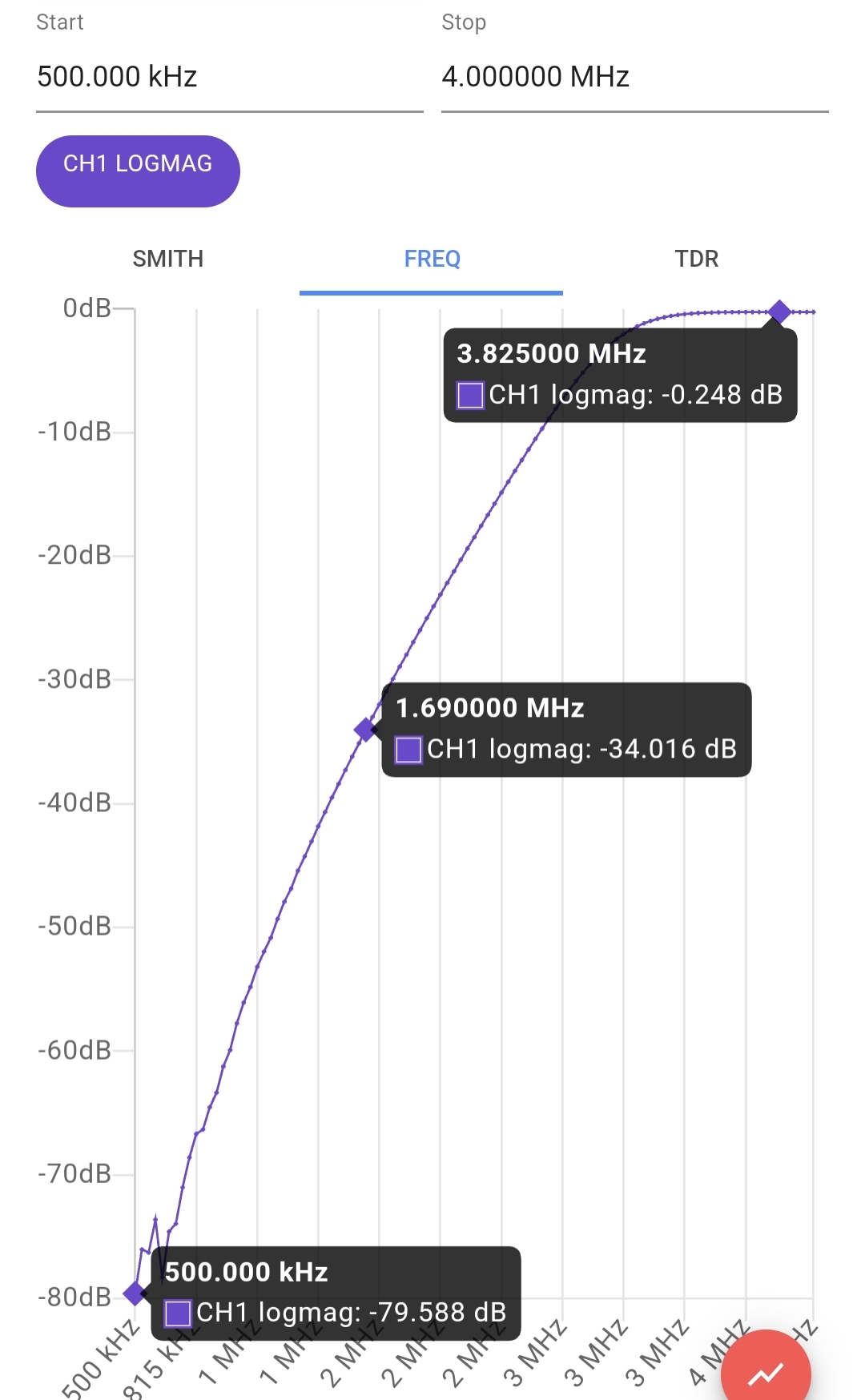

18. Test the filter with your radio or VNA. Congratulations, your filter is now complete!